Description

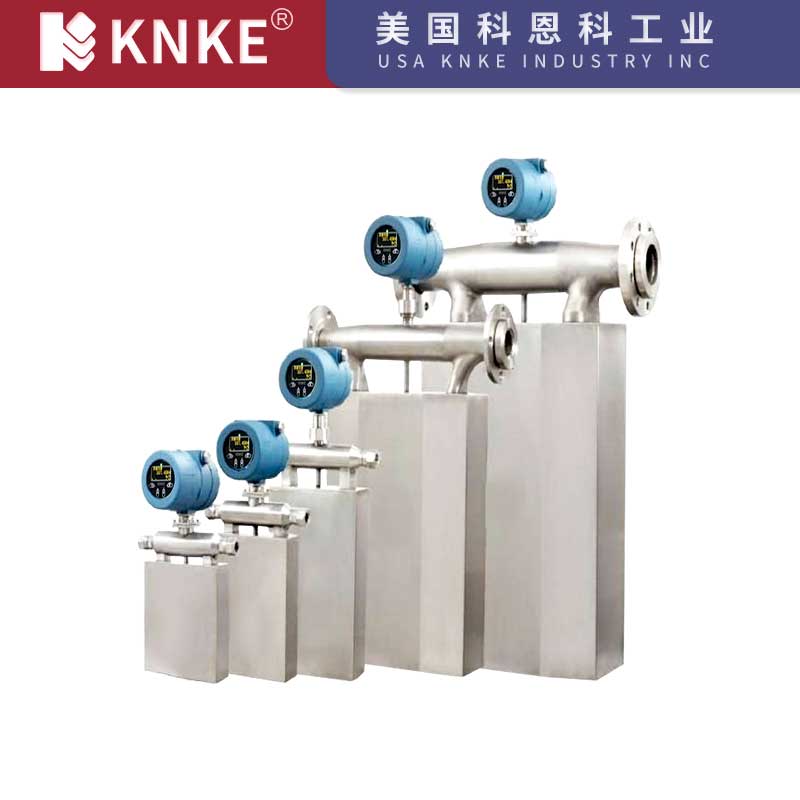

1. Coriolis Flow Meter Product Overview

The KNKE Coriolis Flow Meter (straight tube type) from the USA adopts a straight tube sensor structure, designed based on the principle of Coriolis force. This new type of flow measurement instrument can directly measure the mass flow and density of fluid in closed pipes. It consists of two main components: the flow measurement sensor and the signal converter. The Coriolis flow meter is highly effective for accurately measuring fluid mass flow, which is of great significance for energy metering and process control in chemical reactions.

2. Coriolis Flow Meter Specifications

| Parameter | Description |

| Flow Range Accuracy | 0.1% ~ 0.5% |

| Power Supply | 24VDC (220VAC) |

| Output Signal | 4-20mA + Pulse; HART; Modbus |

| Diameter Range | DN10 ~ DN50 |

| Medium Temperature | -200 ~ 350℃ (customized options available) |

| Material | Measuring Tube: SS316L, Housing: SS304 |

| Pressure Rating | 4MPA (customized options available) |

| Display | Instantaneous + Cumulative + Density + Temperature (mass flow, density, temperature, volume flow, % concentration) |

3. Applicable Media

The KNKE Coriolis Flow Meter is widely applicable for measuring various industrial and commercial fluids, including but not limited to the following:

- Gases: Hydrogen, LPG, liquefied natural gas, liquid hydrogen, liquid helium, liquid nitrogen, liquid carbon dioxide, etc.

- Liquids: Asphalt, crude oil, liquid argon, heavy oil, and other industrial chemical liquids.

This broad range of applicable media makes the Coriolis flow meter highly suitable for precise measurement needs in energy metering, chemical production process control, and measuring complex media.

4. Application Scenarios

The KNKE Coriolis Flow Meter is ideal for a variety of industrial applications due to its high precision and multifunctional characteristics, including but not limited to:

- Oil and Gas: Measurement of crude oil, refined oil, LPG, and natural gas, ensuring accuracy in flow measurement during production and transportation.

- Chemical Industry: Accurate metering of chemicals, ensuring stability in chemical reactions and product quality.

- Metallurgy and Building Materials: Measuring high-temperature and high-pressure media, maintaining quality control in metallurgy and building material production.

- Pulp and Pharmaceutical Industry: Measuring complex media such as slurries and suspensions, improving production efficiency and product quality in pulp and pharmaceutical processes.

- Food and Biotechnology: Accurate metering of liquid raw materials, fermentation solutions, ensuring hygiene and stability in food and biotech production.

- Energy and Aerospace: Precise measurement of high-value energy media and special-use media, ensuring safety and efficiency in energy development and aerospace industries.

The versatility of the KNKE Coriolis Flow Meter makes it an essential measurement tool for many industrial sectors, especially where high accuracy and reliability are required.

5. Coriolis Flow Meter Features

- High Measurement Accuracy: Accuracy ranges from 0.1% to 0.5%.

- Wide Measurement Range: Ensures accuracy with a measurement range of up to 10:1 or 20:1.

- Versatile Applications: Suitable for conventional fluids, as well as industrial media like highly viscous fluids, slurries, and suspensions.

- Multi-Parameter Measurement: Real-time measurement of density and temperature, which can be used to derive solute concentration in a solution.

- Easy Installation: No special requirements for upstream or downstream straight pipe sections.

- Stable Operation: Reliable performance with low maintenance requirements.

6. Coriolis Flow Meter Models

| Model | Flow Range (kg/h) | Diameter (mm) | Zero Stability (kg/h) |

| KNKE-CMF-008 | 960 ~ 1440 | DN8 | 0.144 |

| KNKE-CMF-015 | 3000 ~ 4500 | DN15 | 0.45 |

| KNKE-CMF-020 | 6000 ~ 9000 | DN20 | 0.9 |

| KNKE-CMF-025 | 9600 ~ 14400 | DN25 | 1.44 |

| KNKE-CMF-032 | 18000 ~ 27000 | DN32 | 2.7 |

| KNKE-CMF-040 | 30000 ~ 45000 | DN40 | 4.5 |

| KNKE-CMF-050 | 48000 ~ 72000 | DN50 | 7.2 |

7. Coriolis Flow Meter Dimensions

| Model | A (mm) | B (mm) | C (mm) | Weight (kg) |

| KNKE-CMF-008 | 500 | 263 | 60 | 7.2 |

| KNKE-CMF-015 | 530 | 263 | 60 | 7.5 |

| KNKE-CMF-020 | 620 | 333 | 120 | 23.5 |

| KNKE-CMF-025 | 700 | 333 | 120 | 25.5 |

| KNKE-CMF-032 | 800 | 333 | 120 | 30 |

| KNKE-CMF-040 | 900 | 343 | 140 | 32 |

| KNKE-CMF-050 | 900 | 343 | 140 | 36 |

8. Coriolis Flow Meter Installation Guidelines

- Installation Direction: Ensure that the KNKE-CMF flow meter sensor is installed in line with the fluid flow direction.

- Support Requirements: Since the Coriolis flow meter operates based on vibrating tube technology, provide sturdy support for the sensor and related pipelines to avoid any vibrations that could affect measurement.

- Vibration Isolation: If strong pipe vibrations are unavoidable, use flexible pipes to isolate the sensor from the piping system.

- Flange Connection: During installation, the flange surfaces should be parallel, with the centers of both flanges aligned on the same axis to avoid additional stress.

- Installation Position: When measuring liquid flow, try to ensure that the fluid flows from bottom to top, and avoid installing the instrument at the highest point in the piping to prevent gas accumulation, which may affect measurement accuracy.