Top 7 Check Valve Applications for Pipeline Safety and System Efficiency

A check valve prevents backflow in pipelines, ensuring that fluid flows only in one direction. This simple yet effective device protects systems from damage caused by reverse flow. Various industries rely on check valves to maintain system stability and safeguard equipment. Here are the most common check valve applications and how they enhance pipeline safety.

1. High-Rise Building Water Supply Networks

In high-rise buildings, water pressure can vary significantly between floors. Check valves are crucial in maintaining consistent water flow and pressure. They prevent water from flowing backward, especially in taller buildings where supply demands fluctuate. By installing automatic check valves, buildings can manage pressure changes and ensure a steady water supply throughout the structure.

Benefits:

- Maintains stable water pressure

- Prevents reverse flow into the water supply system

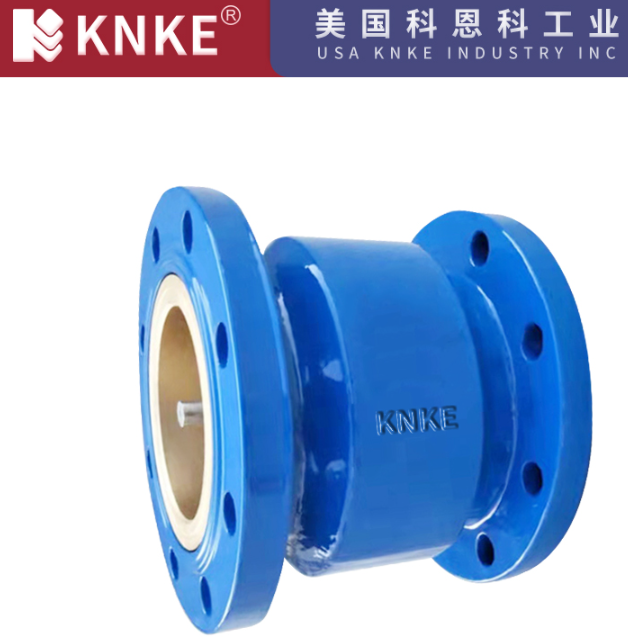

2. Piping Systems for Corrosive Chemical Media

Many industries, such as chemical, pharmaceutical, and petrochemical, transport corrosive fluids. Backflow in these systems could cause severe damage. For this reason, manufacturers use corrosion-resistant check valves. These valves protect pipelines and equipment from aggressive chemicals, ensuring long-term system integrity.

Benefits:

- Prevents corrosive media from flowing backward

- Protects sensitive equipment from damage

3. Wastewater Systems

In wastewater management systems, check valves prevent sewage from flowing back into treatment facilities or homes. Reverse flow can cause contamination and environmental hazards. By installing check valves at discharge points and pump stations, facilities can effectively control fluid flow and avoid pollution risks.

Benefits:

- Prevents sewage backflow

- Protects the environment and water supply systems

4. Water Supply and Drainage Systems

Check valves play a critical role in urban water supply and drainage systems. They ensure water flows in the right direction, preventing contamination in clean water systems. Additionally, they stop stormwater and sewage from flowing back into the drainage network. These valves maintain the efficiency and safety of water systems.

Benefits:

- Prevents contamination of clean water

- Ensures proper drainage and reduces the risk of flooding

5. Submersible Pumps, Drainage, and Sewage Pumps

Check valves protect submersible pumps and sewage pumps from backflow. When the pump turns off, water could flow back into the system, causing damage. Check valves close automatically, stopping reverse flow and preserving the pump’s functionality. They help maintain the pump’s efficiency and extend its lifespan.

Benefits:

- Prevents pump damage

- Increases the reliability of the pumping system

6. Domestic Water Supply Networks

In residential and commercial water systems, check valves prevent water from flowing backward into the system, especially during pipe maintenance or failures. These valves ensure that water quality remains safe and prevent contamination from outside sources. By installing check valves, property owners can protect their water systems and health.

Benefits:

- Safeguards water quality

- Prevents contamination during pipe maintenance or failures

7. Industrial Pipelines in Oil, Chemical, and Metallurgical Sectors

Industries such as oil, chemical, and metallurgy often transport high-pressure and high-temperature fluids. In these conditions, backflow could lead to catastrophic failures. Check valves in these systems ensure that dangerous materials do not flow backward, preventing accidents and maintaining safe operations. They are designed to withstand extreme conditions, ensuring long-term reliability in high-stress environments.

Benefits:

- Prevents backflow of hazardous materials

- Ensures safe operation in high-pressure environments

Choosing the Right Type of Check Valve

Choosing the right check valve for each application is crucial. Various types of check valves suit different operational needs. For example:

- Swing Check Valve: Best for low-flow systems. It uses a disc that swings to block reverse flow.

- Lift Check Valve: Suitable for medium to high-flow systems. The valve’s disc or ball is lifted off the seat by the flow of fluid.

- Ball Check Valve: Used in high-flow, high-pressure systems. A ball blocks reverse flow in this valve.

- Spring-Loaded Check Valve: Ideal for systems with fluctuating flow. It uses a spring mechanism to ensure the valve closes when flow stops.

Check valves are essential for maintaining the integrity of modern pipeline systems. Whether in high-rise buildings, wastewater management, chemical processing, or industrial pipelines, check valves prevent backflow and protect systems from damage. Choosing the right valve for your application is key to maintaining efficiency and safety. By properly selecting and installing check valves, you can ensure the long-term reliability of your system and minimize the risk of costly repairs.

Benefits of Proper Check Valve Selection:

- Prevents backflow and contamination

- Enhances system reliability and safety

- Reduces maintenance and repair costs

By incorporating these essential components into your pipeline system, you can increase operational efficiency, extend the lifespan of your equipment, and ensure safe, uninterrupted service.