The Key Differences: Control Valves vs. Regulating Valves Explained

In the world of industrial automation and fluid control, control valves and regulating valves are two frequently mentioned but often confused concepts. While both are used to manage fluid flow, they have fundamental differences in their operating principles, functions, and applications. Understanding these distinctions is critical for selecting and using the correct valve for any system, directly impacting its efficiency, precision, and safety.

1. Operating Principle & Function: Active vs. Passive Action

Control Valve A control valve is an active actuator and a final control element within an automated system. Its core function is to precisely modulate a fluid’s flow rate, pressure, temperature, or level based on an external command signal.

- How it Works: A control valve requires an external input signal (typically a 4-20mA or 0-10V analog signal from a DCS or PLC). The valve’s actuator (pneumatic, electric, or hydraulic) moves the valve plug to adjust the flow rate precisely according to this signal.

- Function: It acts as an executor, strictly following the control system’s instructions to achieve closed-loop control of a process variable.

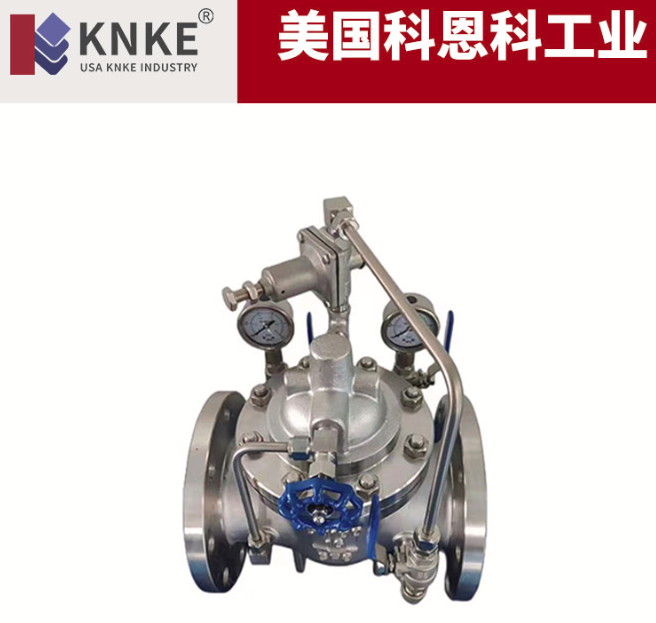

Regulating Valve A regulating valve, in contrast, is a passive actuator. Its operation does not depend on an external control signal; instead, it automatically responds to changes in fluid parameters through its own internal mechanism.

- How it Works: The valve contains a sensing element (like a diaphragm, spring, or bellows). When fluid pressure or temperature changes, this element automatically moves the valve plug, modulating the valve’s opening to restore the desired state.

- Function: It acts as a self-operated regulator, providing automatic, localized control of a fluid parameter without the need for an external power source.

2. Application & Control Method: Macro vs. Micro Control

Control Valve Applications We use control valves extensively in complex, high-precision automation systems where integrated control is a must.

- Characteristics: They are the heart of closed-loop control systems. A sensor constantly monitors a fluid parameter, feeds data back to a controller, and the controller then sends a command to the control valve for adjustment.

- Typical Applications:

- Petrochemical Plants: Precisely controlling temperature and pressure in reaction vessels.

- Power Plants: Regulating boiler feedwater flow and steam pressure.

- Pharmaceutical and Food Industries: Precisely controlling ingredient ratios and sterilization temperatures.

Regulating Valve Applications We primarily use regulating valves for simple, localized fluid control tasks where precision requirements are typically lower than those for control valves.

- Characteristics: They represent open-loop or self-operated control. They don’t need external power or complex control loops.

- Typical Applications:

- Compressed Air Systems: Automatic pressure-reducing valves to lower high-pressure gas to a set value.

- Steam Lines: Self-actuated temperature regulators to maintain a constant temperature.

- Fire Suppression Systems: Relief valves that automatically open when line pressure exceeds a safe limit.

At a Glance: Key Differences Summarized

| Feature | Control Valve | Regulating Valve |

| Operating Principle | Receives an external signal; actively changes opening. | Senses fluid parameters internally; automatically changes opening. |

| Control Method | Closed-loop control; high precision; programmable. | Self-operated control; localized and automatic. |

| Energy Requirement | Requires an external power source (air/electricity). | Self-powered; works without external energy. |

| System Integration | Highly integrated with DCS/PLC systems. | Typically works independently. |

| Primary Function | Precisely modulate flow, pressure, and temperature. | Maintain stable pressure or constant temperature; provide relief. |

A control valve is an extension of a system’s brain, relying on external commands for precise, overarching control of complex processes. In contrast, a regulating valve is a smart sentinel for fluid lines, using its own mechanism to make simple, localized, and automatic adjustments.

When choosing a valve, you should ask yourself: Do you need a precise executor that follows commands, or a reliable guardian that automatically maintains a stable state? Your answer will determine whether you need a control valve or a regulating valve.