Structure and Components of Magnetic Drive Pumps

Magnetic drive pumps are commonly used in industries like chemicals, pharmaceuticals, and petrochemicals. Their unique design helps avoid leakage, making them ideal for handling hazardous, volatile, and corrosive liquids. This article will explore the main components of magnetic drive pumps, special structural designs for different types, and the advantages of their construction.

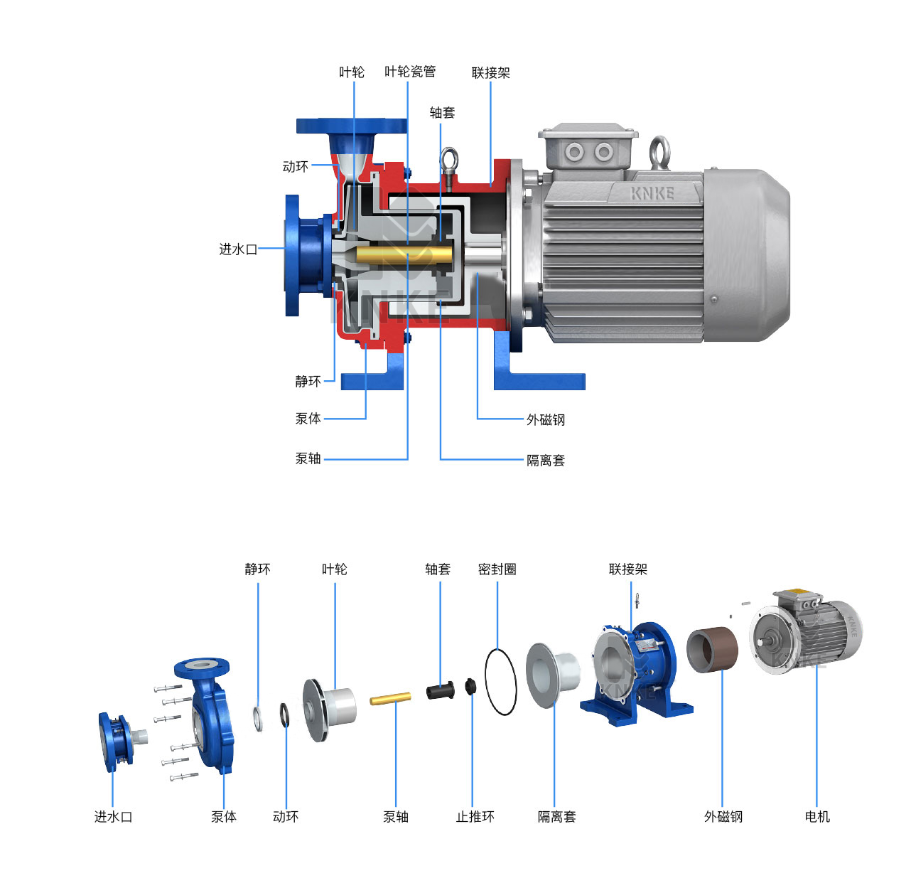

Main Components of a Magnetic Drive Pump

Magnetic drive pumps have several key parts. Each part plays an essential role in the pump’s operation.

- Pump Body

The pump body is the core part of the magnetic drive pump. It helps transport liquids effectively. It includes:- Impeller: Moves the liquid through the system.

- Pump Body (Pressure Chamber): Holds the liquid and provides pressure for pumping.

- Bearings and Shaft Sleeves: Support the pump shaft and ensure smooth movement.

- Pump Cover and Shaft: Seal and support the pump body.

- Magnetic Drive System

The magnetic drive system is crucial for the pump’s operation. It consists of:- Outer Magnetic Rotor: Rotates with the motor.

- Inner Magnetic Rotor: Synchronizes with the outer rotor via magnetic fields.

- Isolation Sleeve: Non-magnetic material that separates the internal components.

- Electric Motor

The electric motor powers the pump. It drives the outer magnetic rotor, which then drives the inner rotor and the pump itself. The motor’s performance directly impacts the pump’s efficiency and longevity. - Additional Components

Other parts of the pump include:- Bracket and Base: Provide support for the pump.

- Intermediate Bearing Housing and Couplings: Used in mid-coupling structures for stability. Direct-coupled structures do not need couplings.

Special Designs in Different Types of Magnetic Drive Pumps

Magnetic drive pumps can have different structures based on specific needs. Some of the most common types are:

- Self-Priming Magnetic Drive Pumps

These pumps have a special design that helps them prime themselves. The structure includes a suction chamber, storage chamber, volute, reflux hole, and gas-liquid separation chamber. When the pump starts, the impeller stirs the liquid with air, creating a gas-liquid mixture. This mixture enters the separation chamber, achieving self-priming. - Stainless Steel Magnetic Drive Pumps

These pumps are made from stainless steel, offering excellent corrosion resistance. They are ideal for transporting corrosive liquids. While the structure is similar to a standard magnetic drive pump, the stainless steel material ensures better durability in harsh environments. - Plastic Magnetic Drive Pumps

These pumps are designed for transporting corrosive liquids like acids and alkalis. They are made of plastic materials, including the pump head, magnetic drive system, electric motor, and connection base. The plastic construction makes them resistant to corrosion and ideal for the chemical industry.

Principle and Advantages of Magnetic Drive Pumps

Magnetic drive pumps operate using a magnetic power transmission system. Unlike traditional pumps that rely on mechanical seals, these pumps use static seals, effectively solving leakage problems. Below are some of the main advantages:

- Zero Leakage

Magnetic drive pumps don’t require mechanical seals, preventing leaks. This is especially important for transporting toxic or hazardous liquids. The absence of leaks protects both the environment and workers. - Energy Efficiency

These pumps are energy-efficient. They help reduce energy waste while also preventing liquid spills that could harm the environment. This makes them a green solution for industrial applications. - High Safety

With no seals that can fail, magnetic drive pumps enhance safety. They are especially useful in high-risk industries, such as chemicals, petrochemicals, and pharmaceuticals, where safety is a top concern. - Corrosion Resistance

Magnetic drive pumps are often made from stainless steel or plastic. These materials resist corrosion, allowing the pumps to handle aggressive liquids. This feature extends the pump’s lifespan, even in tough working conditions.

Magnetic drive pumps are essential in many industries due to their unique, contactless power transmission and zero-leakage design. They offer many advantages, such as energy efficiency, safety, and corrosion resistance. As technology continues to advance, magnetic drive pumps will become even more integral to industries that require safe and efficient liquid transportation.