Imported Flow Meters: Essential Technology for Accurate Industrial Measurement

In today’s industrial landscape, precise measurement of fluid flow is critical for operational efficiency, process optimization, and regulatory compliance. Imported flow meters have emerged as essential instruments that provide accurate, reliable measurements across various industrial applications. This comprehensive guide explores the importance of imported flow meters and their role in modern industrial measurement systems.

Understanding Flow Meters

Flow meters are sophisticated devices designed to measure the volumetric or mass flow rate of liquids, gases, or steam flowing through pipelines. These instruments play a crucial role in industries ranging from oil and gas to chemical processing, water treatment, and manufacturing. The accuracy and reliability of flow measurements directly impact product quality, process control, and operational costs.

The Importance of Quality in Flow Measurement

When it comes to flow measurement, quality cannot be compromised. Imported flow meters often represent the pinnacle of technological advancement, incorporating cutting-edge features and precision engineering that may not be available in locally manufactured alternatives. These instruments undergo rigorous quality control processes and meet international standards, ensuring consistent performance in demanding industrial environments.

Types of Imported Flow Meters

1. Electromagnetic Flow Meters

These meters use electromagnetic induction principles to measure conductive fluids. They offer excellent accuracy, minimal pressure drop, and can handle corrosive liquids effectively.

2. Ultrasonic Flow Meters

Utilizing ultrasonic waves to measure flow, these meters provide non-intrusive measurement capabilities and are ideal for large pipeline applications.

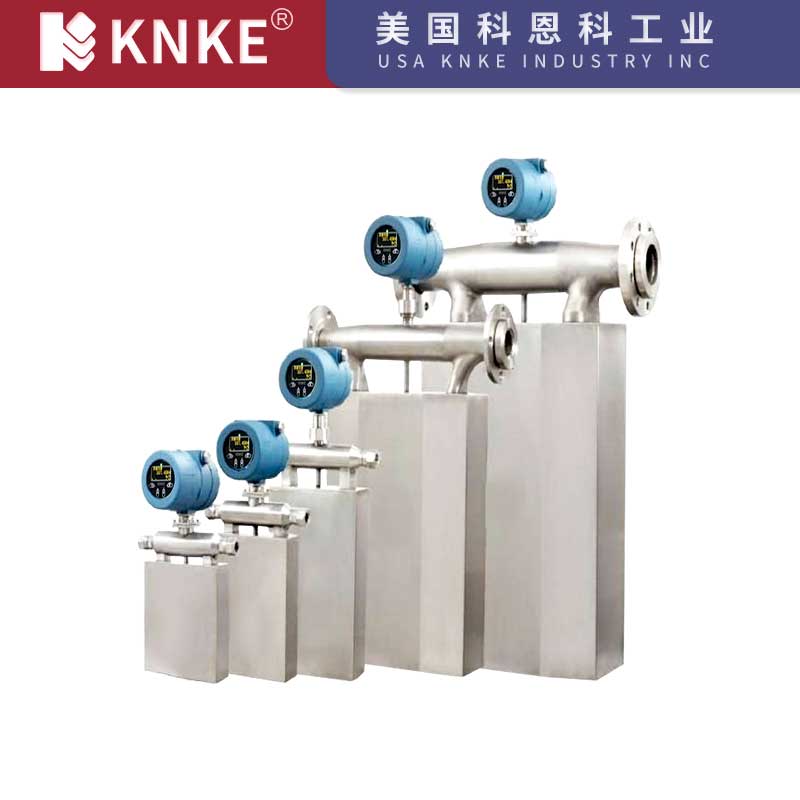

3. Coriolis Flow Meters

Considered among the most accurate flow measurement devices, Coriolis meters measure mass flow directly and can simultaneously measure density and temperature.

4. Vortex Flow Meters

These meters detect vortices shed by a bluff body placed in the flow stream, making them suitable for steam and gas applications.

5. Turbine Flow Meters

Featuring a rotor that spins proportional to fluid velocity, turbine meters offer high accuracy for clean liquids.

Key Advantages of Imported Flow Meters

Superior Technology

Imported flow meters often incorporate the latest technological innovations, including advanced digital signal processing, smart diagnostics, and enhanced communication capabilities.

Proven Reliability

Manufacturers of imported flow meters typically have extensive experience and established reputations for producing reliable, long-lasting instruments.

Comprehensive Support

Leading international manufacturers provide comprehensive technical support, documentation, and training resources to ensure optimal performance.

Regulatory Compliance

Many imported flow meters come pre-certified to meet international standards such as ISO, API, and ASME, simplifying compliance requirements.

Applications in Industrial Automation

Flow meters are integral components of modern industrial automation systems. They provide critical data for:

- Process Control: Real-time flow data enables precise control of industrial processes

- Energy Management: Accurate measurement helps optimize energy consumption

- Quality Assurance: Consistent flow measurement ensures product quality

- Regulatory Reporting: Precise measurements support environmental and safety compliance

Selecting the Right Flow Meter

Choosing the appropriate flow meter requires careful consideration of several factors:

- Fluid Properties: Viscosity, conductivity, temperature, and pressure

- Pipe Size: Diameter and material of the pipeline

- Flow Range: Minimum and maximum flow rates

- Accuracy Requirements: Precision needed for the application

- Environmental Conditions: Temperature, vibration, and hazardous area classifications

- Budget Considerations: Initial cost versus long-term value

KNKE Global: Your Partner in Flow Measurement

At KNKE Global, we understand the critical importance of accurate flow measurement in industrial operations. Our extensive portfolio of imported flow meters represents the best in class from leading international manufacturers. We work closely with our clients to identify the optimal flow measurement solution for their specific applications, ensuring maximum performance, reliability, and value.

Our team of experienced engineers provides comprehensive support throughout the entire lifecycle of your flow measurement system, from initial selection and installation to ongoing maintenance and calibration services.

Conclusion

Imported flow meters represent a wise investment for industries requiring precise, reliable flow measurement. Their superior technology, proven reliability, and comprehensive support make them essential tools for modern industrial operations. By choosing quality imported flow meters, companies can ensure optimal process control, regulatory compliance, and long-term operational success.

For more information about our imported flow meter solutions and how they can benefit your industrial operations, contact KNKE Global today.