Difference Between Wafer Ball Valve and Conventional Ball Valve

In the field of industrial fluid control, ball valves are widely used in various piping systems due to their excellent sealing performance and convenient operation. Among the different types of ball valves, wafer ball valves and conventional ball valves are two common ones. This article will compare the two types from various aspects to help users make informed decisions when selecting valves.

1. Structural Differences

Wafer Ball Valve

The wafer ball valve uses a wafer-type connection, which results in a short structural length and lightweight design, making it suitable for small-diameter pipelines. Compared to traditional flanged connections, wafer ball valves have a simpler structure and are easier to install. Some models are equipped with features like elastic sealing, fire resistance, anti-static structure, and 90° switch positioners, ensuring reliability under specific operating conditions.

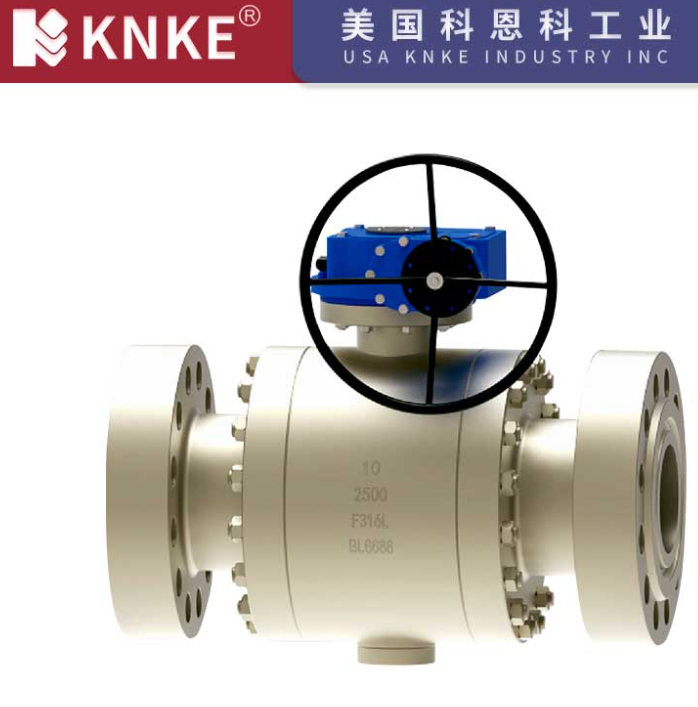

Conventional Ball Valve

Conventional ball valves typically use traditional flanged connections, which have a more complex structure and are bulkier and heavier. These valves are designed to withstand higher pressures and temperatures, requiring stronger materials and more sealing components. They usually need flanges to connect and bolts to secure the seals.

2. Installation Differences

Wafer Ball Valve

The installation of wafer ball valves is straightforward, requiring no additional flanges or bolts. This saves both material and space. As a result, wafer ball valves are suitable for installations in confined spaces, and maintenance is relatively simple.

Conventional Ball Valve

In contrast, conventional ball valves require flanged connections and the tightening of bolts, making the installation process more complicated. The installation of these valves requires more space, and the process becomes more challenging, especially in narrow spaces.

3. Application Differences

Wafer Ball Valve

Wafer ball valves have a narrower application range, typically used in small-diameter pipes, space-constrained areas, and low-pressure systems (recommended PN16 and below). They are commonly used for clean fluid control, such as oil and water, in residential and small industrial pipelines. Due to their simple structure and lower cost, they are ideal for budget-conscious applications.

Conventional Ball Valve

Conventional ball valves have a broader application range, capable of handling large-diameter pipelines, high pressures (PN400), wide temperature ranges (-196°C to 550°C), and corrosive media. These valves are commonly used in the chemical, petroleum, and natural gas industries, where high reliability and durability are essential for extreme conditions.

4. Performance Differences

Wafer Ball Valve

Wafer ball valves provide good sealing performance and are easy to operate, typically with a 90° rotation for quick opening and closing. They offer minimal flow resistance, and full-bore models allow media to pass without loss. These features make them ideal for small-diameter and low-pressure fluid control systems.

Conventional Ball Valve

Conventional ball valves offer excellent sealing performance, with some models using full-lining construction to handle corrosive media. Their adaptability to various operating conditions is superior, especially in high-pressure, high-temperature, and corrosive environments. Although conventional ball valves are less efficient in terms of ease of operation and installation, they provide better reliability and stability in heavy-duty applications.

5. Price and Cost Differences

Wafer Ball Valve

Due to their simple structure and minimal material consumption, wafer ball valves have a lower manufacturing cost and are priced more economically. This makes them an excellent choice for large-scale procurement or budget-conscious projects, offering high value for money.

Conventional Ball Valve

Conventional ball valves are more expensive because of their complex structure and the need for additional components like flanges. Despite the higher cost, these valves offer better performance in high-pressure, high-temperature, and corrosive environments, making them more suitable for demanding industrial applications.

6. Advantages and Disadvantages Comparison

| Type | Advantages | Disadvantages |

|---|---|---|

| Wafer Ball Valve | ① Compact and space-saving; ② Easy installation and maintenance; ③ Cost-effective; ④ Low flow resistance | ① Not suitable for high pressure, high temperature, or corrosive media; ② Limited application range |

| Conventional Ball Valve | ① Suitable for a wide range of applications (high pressure, high temperature, corrosive, etc.); ② Reliable sealing; ③ High reliability | ① Larger size, heavier weight; ② Complex installation, higher cost; ③ More difficult maintenance |

7. Selection Recommendations

Prioritize Wafer Ball Valve:

If the operating conditions involve low pressure, small diameter, limited space, and clean fluids (such as water and oil), and there is a need to control costs, wafer ball valves are the preferred choice. Their simple structure, low cost, and ease of installation and maintenance make them ideal for small industrial and residential applications.

Prioritize Conventional Ball Valve:

If the operating conditions involve high pressure, large diameter, high temperature, corrosive media, or extremely high sealing requirements (such as in natural gas and chemical industries), conventional ball valves should be selected. Despite their higher cost, they offer superior adaptability to harsh conditions and long-term reliability, making them suitable for complex industrial applications.

Both wafer ball valves and conventional ball valves have their own advantages and disadvantages. The key lies in selecting the valve type that best suits the operating conditions. By understanding their structural, performance, application, and installation differences, users can make more informed decisions when purchasing valves for their projects.