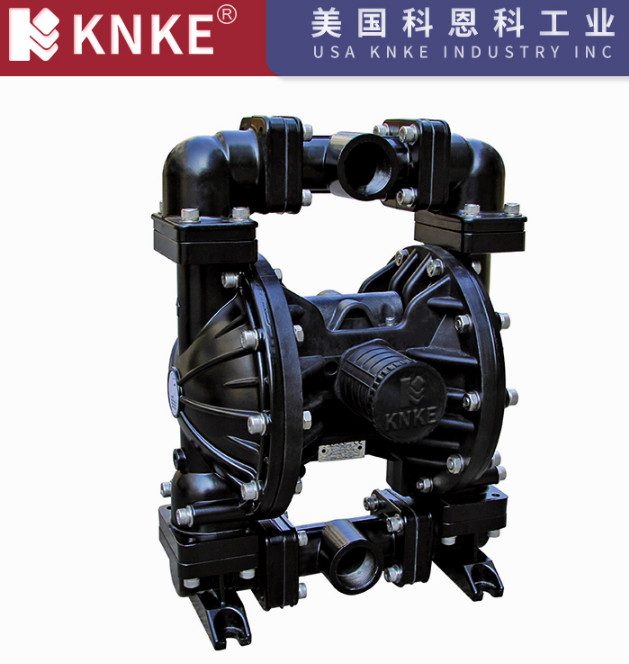

Common Faults and Solutions for Pneumatic Diaphragm Pumps

Pneumatic diaphragm pumps are widely used in various industries and chemical processes due to their simple structure, ease of operation, and strong adaptability. However, over time, these pumps may experience certain faults that affect their performance. This article outlines common faults in pneumatic diaphragm pumps and their corresponding solutions to help users identify issues and perform effective maintenance and repairs.

1. Insufficient Flow Fault and Solutions

Fault Causes

- Leakage in the inlet and outlet valves: Poor sealing of the inlet or outlet valves can cause insufficient flow.

- Damaged diaphragm: A worn or damaged diaphragm directly impacts the flow rate.

- Slow speed or malfunctioning adjustment: If the speed control mechanism is faulty, the pump will not reach the desired flow rate.

Solutions

- Inspect and repair or replace the inlet valve.

- Replace the damaged diaphragm.

- Inspect and adjust the speed control mechanism to ensure it is functioning properly.

2. Oil Leakage Fault and Solutions

Fault Causes

- Damaged or loose sealing gaskets or seals: Worn-out or improperly installed sealing components can cause oil leakage.

Solutions

- Adjust or replace the damaged gaskets or seals.

3. Viscous Operation or Seizure

Fault Causes

Pneumatic diaphragm pumps can experience viscous operation or seize due to various reasons:

- Excessive or insufficient lubrication: Both over-lubrication and under-lubrication can affect pump performance.

- Incorrect lubrication type: Using an unsuitable lubricant can reduce lubrication efficiency.

- Freezing: Freezing of the pump or liquid in cold environments can cause the pump to seize.

- Manifold blockage: Blockages in the manifold can result in slow or halted pump movement.

- Outlet blockage or closed outlet valve: High system pressure or a closed valve can prevent the pump from functioning correctly.

- Cavitation on the suction side: Cavitation on the suction side can hinder proper pump operation.

- Insufficient air intake: Inadequate airflow can cause the pump to malfunction.

- Worn O-rings: Worn or damaged O-rings may cause improper sealing, affecting pump function.

- Steam pressure issues: Unstable steam pressure can affect the pump’s operation.

- Incorrect pump size: If the pump size is not suited for the application, it may cause operational problems.

Solutions

- Ensure proper lubrication, using the correct type and amount.

- Clear any blockages in the pump, air valve, or manifold.

- Check the outlet valve and adjust the system pressure as needed.

- Inspect and replace worn O-rings.

- Verify that the pump specifications match the required application.

4. Low Flow Rate

Fault Causes

- Cavitation marks on the pump body: Cavitation can cause damage to the pump body and reduce flow.

- Valve ball stuck: The valve ball may become stuck due to material mismatches or blockages.

- Clogged inlet pipe: A blocked inlet pipe can reduce the suction capability and flow rate.

Solutions

- Inspect the pump for cavitation marks and adjust the intake pressure or reduce the pump speed if necessary.

- Check that the valve ball material is compatible with the liquid being pumped; replace the valve ball and seat if needed.

- Clear any blockages in the inlet pipe.

5. Failure to Start or Slow Movement

Fault Causes

- Clogged filtration, pressure adjustment, or lubrication devices: A clogged filter or pressure control mechanism can prevent the pump from starting properly.

- Air valve obstructed by debris: Debris blocking the air valve can cause the pump to malfunction.

- Worn spindle and O-ring: Damage to the spindle or O-ring can lead to slow or non-functional pump operation.

Solutions

- Inspect and clean the filter, pressure control, and lubrication devices.

- Remove any debris from the air valve, check for wear on the piston, and replace the piston and O-rings if necessary.

- Inspect the spindle and O-ring for damage and replace them as needed.

6. Liquid Leaking from the Air Chamber Discharge

Fault Causes

- Damaged diaphragm: A ruptured diaphragm is a common cause of liquid leakage.

- Incorrect installation of the diaphragm: If the diaphragm is not properly installed or secured, it may leak.

Solutions

- Check the diaphragm for any damage and replace it if necessary.

- Ensure that the diaphragm is installed correctly and securely.

7. Large Amount of Air Bubbles in Outlet Liquid

Fault Causes

- Damaged diaphragm: A damaged diaphragm may cause air to enter the liquid stream.

- Leakage in the pump body or pipeline: Any leaks in the pump body or pipes can lead to the formation of air bubbles in the liquid.

Solutions

- Check and replace the damaged diaphragm.

- Inspect the pump body and pipeline for leaks and repair as needed.

8. Pump Operates Once and Then Stops

Fault Causes

- Incorrect O-ring positioning: Incorrect positioning of the O-ring can cause the pump’s cycle to stop prematurely.

- Incorrect installation of diaphragm pressure plate: Improper installation of the diaphragm’s pressure plate can prevent normal pump operation.

- Blocked outlet or closed outlet valve: System pressure equal to or exceeding the air source pressure may stop the pump from continuing its cycle.

- Improper installation of the air valve or intermediate gasket: Incorrect installation of these components can cause the pump to fail to complete a full cycle.

Solutions

- Check the position of the O-ring and diaphragm pressure plate, ensuring they are installed correctly.

- Ensure the outlet is not blocked, and the outlet valve is open.

- Inspect the air valve and intermediate gaskets to verify correct installation.

By understanding and addressing these common faults, users can extend the lifespan and improve the efficiency of pneumatic diaphragm pumps. Regular maintenance and timely repairs are essential to keep the pump running smoothly and avoid costly downtime.