The Application of Control Valves

In the intricate world of modern industry, there’s a device that works tirelessly behind the scenes, yet is crucial to the efficiency and safety of processes ranging from oil refining to food processing—the control valve. These seemingly simple mechanical devices are at the heart of automation systems, precisely regulating the flow rate, pressure, temperature, and liquid level of fluids (liquids, gases, steam, or slurries). Without them, many industrial operations we take for granted would be impossible.

How Control Valves Work

Simply put, a control valve works by changing the area of the flow path inside the valve to regulate the fluid’s flow rate. They typically consist of several main parts:

- Valve Body: Contains the fluid passage and the seat.

- Valve Trim: Includes the plug and the seat, which are the parts that directly contact the fluid and regulate its flow.

- Actuator: Receives a control signal (usually pneumatic, electric, or hydraulic) and generates a force or torque to move the valve plug.

- Positioner: An intelligent device that ensures the actuator precisely moves the valve plug to the position indicated by the control signal.

Through the coordinated action of these components, control valves can dynamically adjust the amount of fluid passing through them, based on signals from a process controller, thereby maintaining process variables at their setpoints.

Wide-Ranging Applications

The applications of control valves are incredibly broad, covering almost every industrial sector that requires precise control over fluid behavior:

1. Oil and Gas Industry

In refineries and natural gas processing plants, control valves are indispensable. They regulate the flow of crude oil and natural gas in pipelines, control pressure and temperature in separators, reactors, and distillation columns, and ensure product quality and production safety. For example, they can precisely control the amount of fuel entering a furnace or adjust the reflux at the top of a distillation column to optimize product separation.

2. Chemical Industry

In chemical plants, various chemical reactions need to occur under strictly controlled conditions. Control valves are used for precise proportioning of reactants, controlling the temperature and pressure of reaction vessels, and regulating product transfer. Even a slight deviation can lead to off-spec products or safety incidents.

3. Power Generation Industry

In power plants, whether coal-fired, gas-fired, or nuclear, control valves play a critical role. They regulate boiler feedwater flow, steam pressure and temperature, and control cooling water circulation. Efficient steam flow control is essential for maintaining stable generator operation and improving energy conversion efficiency.

4. Food and Beverage Industry

The production processes for food and beverages demand high levels of hygiene and precise control. Control valves are used to regulate the mixing of various liquids, control temperature during pasteurization, manage flow in CIP (Clean-in-Place) systems, and ensure accurate dispensing in filling lines. Hygienic control valve designs prevent product contamination.

5. Pharmaceutical Industry

The pharmaceutical industry has even more stringent requirements for precision and sterile environments. Control valves function in bioreactors, fermenters, and purification systems, controlling media flow, temperature, and pH levels to ensure drug quality and safety.

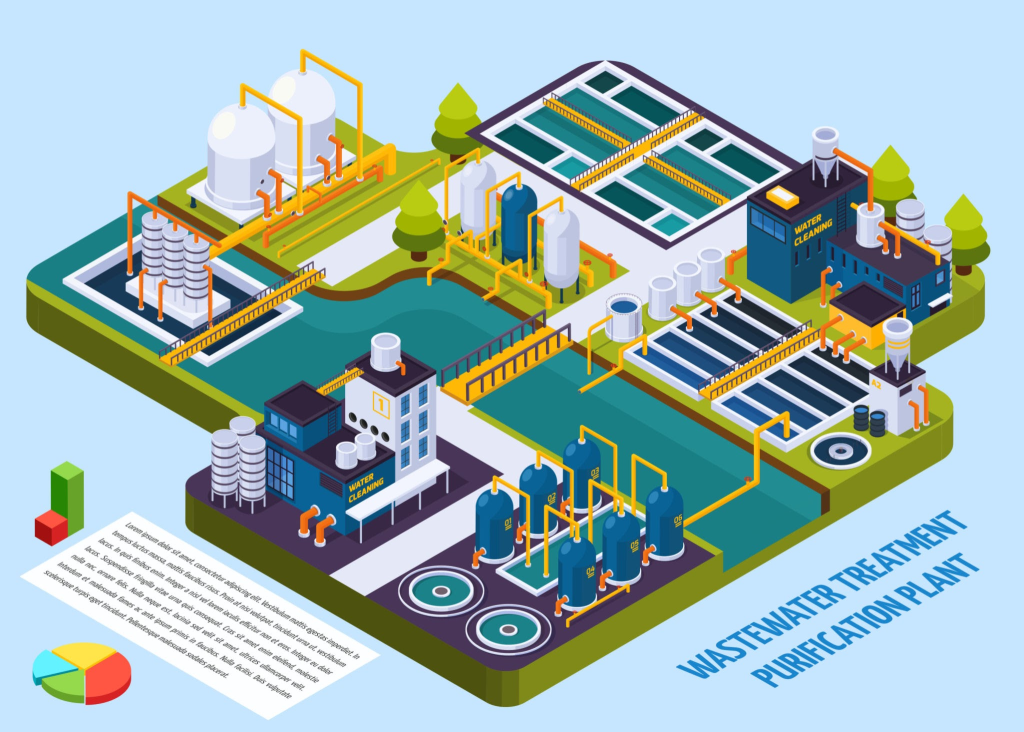

6. Water and Wastewater Treatment

In municipal and industrial water treatment plants, control valves regulate the output flow of pumps, control pressure in filtration systems and membrane separation processes, and adjust the dosage of chemicals. They are key to ensuring water quality compliance and effective wastewater treatment.

Future Outlook

With the advent of Industry 4.0 and the Internet of Things (IoT) technologies, control valves are continuously evolving. Smart control valves integrate advanced sensors and communication technologies, enabling self-diagnosis, predictive maintenance, and seamless integration with broader control systems. This not only improves equipment reliability and operational efficiency but also opens up possibilities for even more refined process optimization.

In conclusion, control valves are the unsung heroes of modern industry. They work tirelessly behind the scenes, ensuring the smooth operation, product quality, and production safety of industries worldwide through precise fluid control. As technology advances, they will continue to play an indispensable role in building a smarter, more efficient industrial future.